Neutron optics R&D

Neutron Optics

Well-designed optical elements play a crucial role in maximising neutron flux at the sample, with carefully optimised systems capable of increasing intensities by orders of magnitude. When combined with precise direction and energy tuning, neutron polarisation techniques enable researchers to investigate complex physical phenomena with exceptional sensitivity, particularly in the study of magnetism.

Contact

Pierre COURTOIS

Head of Service

courtois@ill.fr

Tel. +33 4 76 20 70 16

Neutron technologies brochure

CRYSTAL MONOCHROMATORS

Crystal monochromators are the most efficient method for producing intense beams of monochromatic neutrons from a ‘white’ neutron source. By exploiting Bragg diffraction, monochromator crystals reflect a specific wavelength band, with the band width determined by the crystal mosaic spread and the divergence of the incident beam. Mosaic crystals are often preferred over perfect crystals, as their mosaicity can better match the divergence of the incoming beam in the scattering plane, optimising the intensity of Bragg-scattered neutrons. Commonly used materials include highly oriented pyrolytic graphite (HOPG), copper, germanium, silicon, and Heusler crystals for polarised neutron applications.

The ILL is a leader in the production of high-quality monochromator crystals and assemblies, which are integral to many of our advanced neutron instruments.

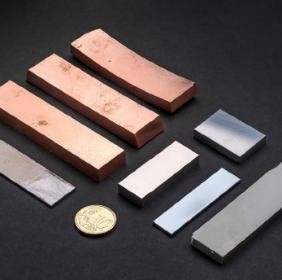

COPPER CRYSTAL MONOCHROMATORS

Copper mosaic crystals exhibit excellent neutron properties, making them highly efficient for neutron monochromators. Their small lattice spacing and strong reflectivity make them ideal for selecting short-wavelength neutrons (l < 1.5 Å) while preserving good resolution. Starting from high-quality single crystals, the mosaic distribution can be further refined by high-temperature plastic deformation, allowing precise tuning of crystal properties to ensure optimal performance across different neutron instruments.

SILICON CRYSTALS FOR ADVANCED OPTICAL COMPONENTS

MARMOT Complete Analyser

- 30 cassette units

- 2790 silicon blades

- 75° angle coverage

MARMOT Silicon Analyser unit

• 43 stacks of 2 Si (111) blades, 1 mm thick

• Blade size: 197 mm x 19 mm to 182 mm x 36 mm

• Radius of curvature: 2400 mm to 2800 mm

High-temperature plastic deformation makes it possible to produce curved silicon crystals with a precise, permanent shape, without needing extra support structures. These crystals can be used to develop optical components that analyze a continuous range of energies or wavelengths while covering many scattering angles. This is a major step forward for neutron optics, especially in triple-axis spectroscopy.

SUPERMIRRORS

WASP Analyzer (1°)

37 Co/Ti/Gd Super-mirrors

D17 analyzer

400 Fe/Si/Gd Super-Mirrors

D17 analyzer

400 Fe/Si/Gd Super-Mirrors

Supermirrors are multilayer structures designed to reflect neutrons at angles exceeding the critical angle. These devices consist of alternating layers of materials with varying neutron scattering lengths. The performance of these supermirrors depends on layer thickness, composition, and perfection.

At ILL, supermirrors are manufactured using magnetron sputtering to deposit materials like Ni, Ti, Si, Co, Fe, and Gd with precise control of layer thickness on the nanometre scale.

Polarising supermirrors use alternating magnetic material layers like Co-Ti or Fe-Si to preferentially reflect neutrons of one spin state while absorbing or transmitting the other. Substrate choice and geometry also play a crucial role in optimising performance.

POLARISED 3He

³He only absorbs neutrons with the opposite spin to that of the ³He nucleus, while its scattering cross-section is extremely small and essentially isotropic. These characteristics make polarised ³He neutron spin filters (NSFs) highly efficient and a very "clean" technology for polarised neutron techniques. Polarised ³He gas serves as a neutron spin filter, which can be used either to polarise the incident beam or for spin analysis of scattered neutrons after the sample.

TYREX 2

The TYREX2 machine at ILL is a specialised device for producing polarised ³He gas, also known as the "³He pumping station". It combines laser optical pumping, gas compression, and magnetic fields to achieve high polarisation levels of ³He nuclei through a process called Metastability Exchange Optical Pumping (MEOP).

TYREX2 is the latest advanced ³He gas polarisation system, the result of over 20 years of continuous development by specialised teams at ILL.

3HE SPIN FILTER

Technical specifications :

• Production rate: 2.5 bar.litre/hour

• Polarisation: > 80%

• Pressure: up to 4 bar

Polarised ³He gas is loaded from the TYREX2 pumping station into neutron spin filter cells (NSF) for transport and installation on polarised neutron instrumentation. The quality of the spin filter cells is crucial for maintaining polarisation and ensuring long relaxation times of the polarised ³He gas.

ADVANCED POLARISATION ANALYSIS: PASTIS3

The ability to control the polarisation direction of ³He nuclei using external magnetic fields makes ³He spin filters an exceptionally versatile tool for neutron polarisation analysis. By adjusting the magnetic field direction, the polarisation of the ³He nuclei can be aligned or rotated, enabling full XYZ polarisation analysis experiments.

This method is powerful for separating magnetic, nuclear coherent, and incoherent scattering, and is particularly well-suited for neutron instruments with wide-angle polarisation analysis.

(pdf - 28 Mi)

(pdf - 28 Mi)