Helium recovery

The helium recovery

In the seventies liquid nitrogen was relatively cheap (<0.5 €/litre in 2014 rates), but helium was already expensive (6-8 €).

Dominique Brochier came from a "poor" low-temperature laboratory and immediately started working on a recovery system for the whole of the ILL. The system started up in 1972 and rapidly enabled the ILL to recycle 90% of its helium over the years; as we will see further on, this brought major savings for the ILL. The system has become so well-known now that it's affectionately known as "la récup".

From the very beginning the system included a means of compressing the gas, to be able to transport it to the CENG. Dominique Brochier says that he made the calculations for the compressors, but it was Gabriel Prati who did the rest, as he was familiar with pressure loss problems. The tubing is all in copper. Why? Brochier was hesitating between plastic and copper, but a plumber friend told him "Do it in copper!", so he did.

Once the gas has been recovered and compressed, it is sent to the CNRS or CEA liquefiers via a copper pipeline nearly 1.5 km long (with an internal diameter of about 5 mm); the line crosses the area occupied today by ST Microelectronics. The gas is transferred thanks to the difference in pressure between the bottles of helium under high pressure and the low-pressure gas holders near the liquefiers. According to the CEA there were about 8 km of piping on the Grenoble "Scientific Polygon" in 2015, for the transfer of helium from one lab to another.

(pdf - 3.07 Mi)

(pdf - 3.07 Mi)Old-time calligraphy!

©May 1976, ILL Marcello Brancaleone

(pdf - 137 Ki)

(pdf - 137 Ki)The "Récup'" gets organised!

©1976, ILL Marcello Brancaleone

(pdf - 1.20 Mi)

(pdf - 1.20 Mi)Corblin compressor

©1986, ILL Marcello Brancaleone

The helium "recoverers”

Helium recovery was therefore initiated by Dominique Brochier and Gabriel Prati (who was to die in an accident in 1976).

Marcello Brancaleone took over operations until his retirement in 2007. The archives tell of work by Klaus Gobretch and J. Mary (SPR). In 1978 they published a study of the risks associated with the use and recovery of helium on the instruments.

Eddy Lelièvre-Berna and his team (SANE) later set about modernising the equipment, reducing the losses to about 5%. The “récup” facility was improved; a regular maintenance programme was introduced (vases, cryostats and He pumps), and the increasingly complex management operations were computerised. In fact the meters were linked to the ILL intranet and SANE developed He4Ever, a pair of iPhone applications - the one, a mobile terminal for data entry, and the other a means of calculating the movement of helium. This gives the ILL automatic monthly and annual reports for the CRG, CEA, CNRS, ESRF and IBS instruments.

Development

We can see how the "récup" has developed by looking at its compressors and the container used for interim storage.

The compressors

- 1973: 30 m3/h LUCHARD HE 40 compressor in the diesels room.

- 1986: Corblin diaphragm compressor. The technology as ideal on paper, but it generated condensation problems and the membranes often failed.

- 1989: Corblin compressor replaced by an 85 m3/h Compair-Luchard HE 110.

- 1995: When the ESRF joined the scheme, the HE 110 compressor proved insufficient for the job and the backup machine, the old 30 m3/h HE 40 dating back to 1972, was beginning to show its age. The HE 40 was therefore given to the CENG's diving club, for filling up their bottles, and an HE 110 came in to replace it.

- 2015: In 2015, therefore, there are 2 Compair-Luchard HE compressors (VHP36 MK1) in use, one from 1988 and the other from 1995.

The gas holder

From 1972 to 2005 ILL used a 7 m3 Zodiac-brand gas bag. In 2005 Marcello transferred the flexible gasometer from ILL 15 to the main stores. The bag was replaced by a 16 m3 model with a different brand (19 m3 according to a plan dated 12 April 2005); however it was poorly installed and soon gave up the ghost. In 2007 it was replaced by a 20 m3 Zodiac bag which is still in use today.

Successive extensions

Discussions started in 1992 on bringing the ESRF on board. An agreement was signed in March 1995 and a "limited" connection was established on 17 July 1995. A fuller contract was signed in 2004.

When the IBS arrived on the EPN Campus it was interested in recovering the vapourised helium in the big cryomagnets on its NMR spectrometers; although they don't consume much helium, there are significant losses during the transfers. In October a 430-metre pipe was installed between the ILL and the IBS (stainless steel tube with 80mm internal diameter). As the helium flow rates vary a lot (they are low when NMR measurements are being taken and high when the NMR cryomagnets are being filled), low- and high-flow rate meters have been installed in parallel, to record automatically the volumes of gas recovered.

A technical success and source of huge savings

The "Récup." is one of the practices distinguishing the ILL from other neutron centres.

There's no doubt as to its utility - as proved by the extension of the network to the ESRF and then to the IBS. In 2014 the SNS (USA) was still not recovering its helium; ISIS (UK) was starting to think about it, and Berlin had installed a system but was still losing 40% of its gas. In the early 2000s FRM-II decided not to install a system as they thought that cryocoolers would be replacing liquid helium cryostats. They are now regretting the decision, as they find they can't use their 15T cryomagnet given the high cost of helium (it cost about 10 000 € a week in 2014 to cool and use the coil). As for the future ESS (Sweden), no decision had been made in early 2015.

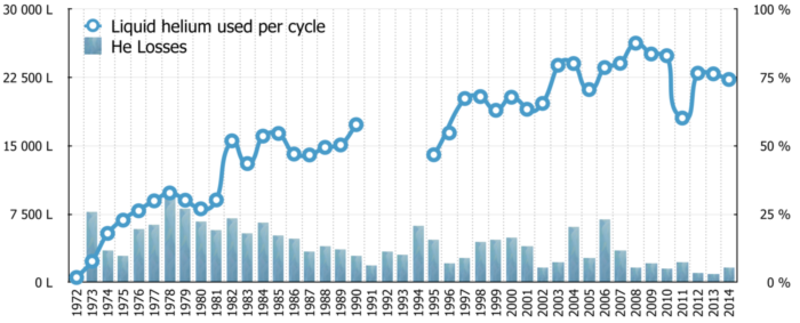

Eddy Lelièvre-Berna has calculated that the ILL used 2,525,706 litres of liquid helium from 1972 to 2014 - 87% recycled. The recycling has resulted in savings of 12.6 M€ for the ILL over the period - a major technical and financial achievement.

(png - 177 Ki)

(png - 177 Ki)Helium use at the ILL 1972 to 2014.

The constant rise reflects the growing importance for scientists of low temperatures and intense magnetic fields.