Temperature Controller (Model 340)

Cryogenic Temperature Controller

In 2005-2007, the replacement of the Carbon and Platinum probes with Cernox thermometers (Cernox CX-1050) has allowed us to start using commercial cryogenic temperature controllers. Indeed, only the aging temperature controller developed at ILL in the late 80s (called ILL-SEC) was able to regulate the temperature from two sensors covering overlapping ranges (1-50 K with the Carbon and 20-320 K with the Pt100).

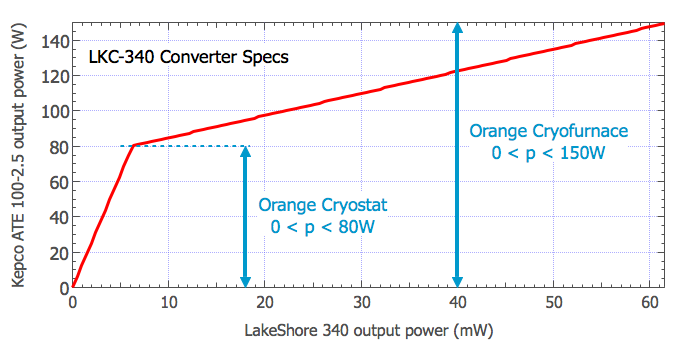

After testing several products, we have chosen the LakeShore Model 340 shown below that is widely used at research facilities. However, it can only provide 50 W of heating power (we use 50 Ω heater resistances) and can only store 40 calibration curves. The first problem is fixed by using a Kepco ATE 100-2.5 power amplifier.

We show below the recommended zone settings for our cryostats and cryofurnaces. Enter these parameters for each zone and for the control loop #1. When complete, press the Save Screen key to store them in the LakeShore memory and switch on the heater by pressing the Heater Range key. We also invite you to check that the right calibration curves are selected. To determine which calibration curve should be used, please visit the Equipment section and look for your equipment.

ATTENTION: You cannot enter the settings of different cryostats in different zones (e.g. zones 1 and 2 for Ø49 Orange Cryostat and zones 3 and 4 for Ø100 Orange Cryostats). The LakeShore determines the zone to apply from the measured temperature, starting from zone 1.

LakeShore 340 Manual

Kepco ATE Specifications

Zone Settings for Orange Cryostats

These values will allow you to establish initial parameter settings and evaluate closed loop operation with your equipment. You can explore different parameters and you may find better values but that can only be done at your own risk.

| Zone | Top of the zone (K) | Proportional (P) | Integral (I) | Derivative (D) | Manual Ouput (%) | Heater Range |

|---|---|---|---|---|---|---|

| 1 | 10 | 25.0 | 50.0 | 0 | 0.00 | 6.2 mW |

| 2 | 120 | 50.0 | 50.0 | 25 | 0.00 | 6.2 mW |

| 3 | 320 | 100.0 | 50.0 | 25 | 0.00 | 6.2 mW |

| Zone | Top of the zone (K) | Proportional (P) | Integral (I) | Derivative (D) | Manual Ouput (%) | Heater Range |

|---|---|---|---|---|---|---|

| 1 | 10 | 25.0 | 50.0 | 0 | 0.00 | 6.2 mW |

| 2 | 320 | 250.0 | 100.0 | 0.0 | 0.00 | 6.2 mW |

| Zone | Top of the zone (K) | Proportional (P) | Integral (I) | Derivative (D) | Manual Ouput (%) | Heater Range |

|---|---|---|---|---|---|---|

| 1 | 10 | 20.0 | 30.0 | 0 | 0.00 | 6.2 mW |

| 2 | 320 | 30.0 | 30.0 | 40 | 0.00 | 6.2 mW |

Zone Settings for Orange Cryofurnaces

These values will allow you to establish initial parameter settings and evaluate closed loop operation with your equipment. You can explore different parameters and you may find better values but that can only be done at your own risk.

| Zone | Top of the zone (K) | Proportional (P) | Integral (I) | Derivative (D) | Manual Ouput (%) | Heater Range |

|---|---|---|---|---|---|---|

| 1 | 10 | 25.0 | 50.0 | 0 | 0.00 | 62 mW |

| 2 | 40 | 35.0 | 75.0 | 0 | 0.00 | 62 mW |

| 3 | 550 | 70.0 | 75.0 | 10 | 0.00 | 62 mW |

| Zone | Top of the zone (K) | Proportional (P) | Integral (I) | Derivative (D) | Manual Ouput (%) | Heater Range |

|---|---|---|---|---|---|---|

| 1 | 10 | 25.0 | 50.0 | 0 | 0.00 | 62 mW |

| 2 | 40 | 35.0 | 75.0 | 0 | 0.00 | 62 mW |

| 3 | 550 | 70.0 | 75.0 | 10 | 0.00 | 62 mW |

Zone Settings for Cryogen-free Orange Cryostats

These values will allow you to establish initial parameter settings and evaluate closed loop operation with your equipment. You can explore different parameters and you may find better values but that can only be done at your own risk.

| Zone | Top of the zone (K) | Proportional (P) | Integral (I) | Derivative (D) | Manual Ouput (%) | Heater Range |

|---|---|---|---|---|---|---|

| 1 | 75 | 100.0 | 30.0 | 10.0 | 0.00 | 62 mW |

| 2 | 320 | 180.0 | 5.0 | 10.0 | 0.00 | 62 mW |

| Zone | Top of the zone (K) | Proportional (P) | Integral (I) | Derivative (D) | Manual Ouput (%) | Heater Range |

|---|---|---|---|---|---|---|

| 1 | 50 | 250.0 | 0.0 | 0.0 | 0.00 | 62 mW |

| 2 | 300 | 400.0 | 0.0 | 0.0 | 0.00 | 62 mW |

| Zone | Top of the zone (K) | Proportional (P) | Integral (I) | Derivative (D) | Manual Ouput (%) | Heater Range |

|---|---|---|---|---|---|---|

| 1 | 60 | 50.0 | 1430.0 | 20.0 | 0.00 | 62 mW |

| 2 | 100 | 500.0 | 20.0 | 12.0 | 0.00 | 62 mW |

| 3 | 300 | 500.0 | 50.0 | 15.0 | 0.00 | 62 mW |

| 4 | 340 | 400.0 | 17.0 | 0.0 | 0.00 | 62 mW |

| 5 | 380 | 290.0 | 20.0 | 0.0 | 0.00 | 62 mW |

| 6 | 600 | 135.0 | 20.0 | 0.0 | 0.00 | 62 mW |

Zone Settings for Cryogen-free Joule-Thomson Cryostats on cradles

These values will allow you to establish initial parameter settings and evaluate closed loop operation with your equipment. You can explore different parameters and you may find better values but that can only be done at your own risk.

| Zone | Top of the zone (K) | Proportional (P) | Integral (I) | Derivative (D) | Manual Ouput (%) | Heater Range |

|---|---|---|---|---|---|---|

| 1 | - | - | - | - | 0.00 | - |

| 2 | - | - | - | - | 0.00 | - |

| 3 | - | - | - | - | 0.00 | - |

| 4 | - | - | - | - | 0.00 | - |

| 5 | - | - | - | - | 0.00 | - |

| 6 | - | - | - | - | 0.00 | - |

LKC-340 Converter

The LKC-340 electronics links the LakeShore Model 340 temperature controller to the Kepco ATE 100-2.5 power amplifier. With this electronics, the power amplifier is protected against abnormal LakeShore output voltages and delivers up to 2.5 times the power provided by a LakeShore. The typical use is described by the graph plotted below. When the 6.2mW heater range is selected in the LakeShore, a maximum power of 80W acceptable for a cryostat is delivered. When using a cryofurnace or a cryogen-free cryostat, this power is almost doubled while the heater range is increased by a decade.

Instruction Manual

When installing a cryostat, cryofurnace or cryomagnet, the settings of the LakeShore 340 temperature controller must be verified and changed following the procedures detailed below. When complete, do not forget to switch on the heater by pressing the Heater Range key.

Calibration curves

Thermometers are installed on the heat exchanger of the variable temperature inserts and at the bottom of the sample sticks. Sometimes, there are also a few other thermometers for specific purposes. Generally, we use Cernox CX1050 sensors in cryostats and RhFe sensors in cryofurnaces. The thermometers are referenced with a serial number which is determined by visiting the Equipment section above: by clicking on the cryostat code name, you get the serial number of the thermometers. You can even download the calibration curves compatible with the LakeShore 340.

By convention, the Cernox or Rhodium Iron sensor of the heat exchanger (regulation) is plugged to the Channel A of the LakeShore. The thermometer of the sample is plugged to the Channel C. In most cases, there are also Pt100 sensors attached to our equipments. They can be read with the Channels B and D respectively but they are used as spare thermometers; when the Cernox or Rhodium Iron sensors cannot be read correctly.

- On the LakeShore, press the Input Setup key to display the INPUT SETUP screen.

- Use the Up or Down key to select Channel A.

- Press the Next Setting key until the Type field is highlighted. Use the Up or Down key to select the sensor you wish, e.g. Cernox, Rhodium Iron, etc.

- Press the Previous Setting key to highlight the Curve field. Use the Up or Down key to select the calibration curve you wish.

- Press the Previous Setting key to highlight the Therm Comp field. Use the Up or Down key to select ON for a Cernox and OFF for a Pt100 or a RhFe.

- Press the Previous Setting key to highlight the Enable field. Use the Up or Down key to select ON.

- Press the Previous Setting key to highlight the Input field. Repeat the sequence with channel B, C and D from step #3.

- Press the Save Screen key to save the settings.

- Press again the Save Screen key to return to the main panel.

Control setup

These settings normally needs to be entered only once. They do not depend on the equipment unless for very particular reasons.

- On the LakeShore, press the Control Setup key to display the CONTROL SETUP screen.

- Use the Up or Down key to select Loop 1.

- Press the Next Setting key to highlight the Enable field. Select ON with the Up and Downkeys.

- Press the Next Setting key to highlight the Power Up field. Select ON with the Up and Down keys.

- Press the Next Setting key to highlight the Setp Unit field. Select TEMP K with the Up and Down keys.

- Press the Next Setting key to highlight the Htr Ω field. Enter the value 1000 with the number keys.

- Press the Next Setting key to highlight the Ctrl Mode field. Select ZONEwith the Up and Down keys.

- Press the Next Setting key to highlight the Filter field. Switch ON with the Up and Down keys.

- Press the Save Screen key to save the settings.

- Press again the Save Screen key to return to the main panel.

Control limits

The limits obviously depend on the type of equipment you are using. For orange cryostats, the maximum allowable temperature is 320K and the maximum heating power is 50W. For orange furnaces, these limits are respectively 560K and 150W. With the Kepco power amplifier connected to the LakeShore with the LKC-340 cable, the maximum heating power delivered by the LakeShore becomes 6.2mW and 62mW respectively.

For an orange cryostat or a cryomagnet:

- On the LakeShore, press the Control Setup key to display the CONTROL SETUP screen.

- Use the Up or Down key to select Loop 1.

- Press the MORE key to display the CONTROL LIMITS screen

- Press the Next Setting key to highlight the Temp field. Enter the value 320 with the number keys.

- Press the Next Setting key until the Max Htr I is highlighted. Use the Up or Down key to select the current 0.25A.

- Press the Next Setting key to highlight the Max Range field. Use the Up or Down key to select the power 6.2mW.

- Press the Save Screen key to save the settings.

- Press again the Save Screen key to return to the main panel.

For a cryofurnace

- On the LakeShore, press the Control Setup key to display the CONTROL SETUP screen.

- Use the Up or Down key to select Loop 1.

- Press the MORE key to display the CONTROL LIMITS screen

- Press the Next Setting key to highlight the Temp field. Enter the value 560 with the number keys.

- Press the Next Setting key until the Max Htr I is highlighted. Use the Up or Down key to select the current 0.25A.

- Press the Next Setting key to highlight the Max Range field. Use the Up or Down key to select the power 62mW.

- Press the Save Screen key to save the settings.

- Press again the Save Screen key to return to the main panel.

Zone control data entry

The LakeShore 340 allows the user to establish up to 10 custom temperature zones where the controller automatically uses pre-programmed PID settings and heater range. These values have been determined at the cryogeny lab. for families of cryostats and must be entered in the controller after installing a new type of cryostat. We describe below the procedure to follow for entering these settings:

- On the LakeShore, press the Zone Settings key to display the ZONE SETTINGS screen.

- Use the Up or Down key to select Loop 1.

- Press the Next Setting key to highlight the Top value of the first row.

- Use the numerical keypad and the Enter key to enter new zone values. Parameters that can be specified are Top of the zone (in K), proportional (P), integral (I), derivative (D), Manual Output in percent (MOut%), and Heater Range. Enter these parameters for each zone.

- When complete, press the Save Screen key to save the settings.

- Press again the Save Screen key to return to the main panel.

- Once the zones are programmed, you must place the controller in zone mode. This is described below, together with other parameters.

(pdf - 2.10 Mi)

(pdf - 2.10 Mi) (pdf - 802 Ki)

(pdf - 802 Ki)