Page 243 - Neutrons for Sciences and Society

P. 243

2018 UPDATE: The ILL between 2005 and 2018

proprietary research), complementing the core subjects studied at ILL (physics, chemistry, biology ...). Some examples are presented below:

Neutrons and technological progress

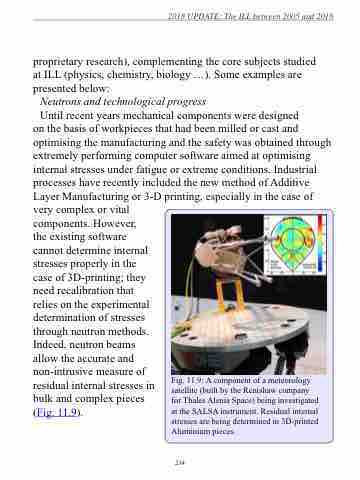

Until recent years mechanical components were designed

on the basis of workpieces that had been milled or cast and optimising the manufacturing and the safety was obtained through extremely performing computer software aimed at optimising internal stresses under fatigue or extreme conditions. Industrial processes have recently included the new method of Additive Layer Manufacturing or 3-D printing, especially in the case of very complex or vital

components. However,

the existing software

cannot determine internal

stresses properly in the

case of 3D-printing; they

need recalibration that

relies on the experimental

determination of stresses

through neutron methods.

Indeed, neutron beams

allow the accurate and

non-intrusive measure of

residual internal stresses in

bulk and complex pieces

(Fig. 11.9).

Fig. 11.9: A component of a meteorology satellite (built by the Renishaw company for Thales Alenia Space) being investigated at the SALSA instrument. Residual internal stresses are being determined in 3D-printed Aluminium pieces.

234