Dilution inserts

Dilution inserts

With the Orange cryostats quickly proving to be both reliable and easy to use, efforts to extend their initial temperature range soon followed (1.5 K - 300 K).

An increase towards the higher end of the temperature scale was achieved in 1984, with the development of a “cryofurnace” variation covering the 1.5 K to 500 K range.

To reach the lower end of the temperature scale, conventional dilution cryostats had to be used, which was not very practical. Several teams therefore set about, independently and with varying degrees of success, trying to extend the possibilities of conventional cryostats towards very low temperatures:

- Oxford Instruments turned their efforts very early on to designing a dilution insert (to be confirmed). The problem to be solved was how to develop a 1 K stage (at which the helium condenses).

- 1980: the PhD thesis produced by Michel Caussignac and supervised by Alain Benoît describes a very compact device, without a 1 K mixing chamber, which can be considered as the first operational dilution insert.

- At the same time, at the ILL, Klaus Gobrecht had developed a pure helium-3 stage making it possible to reach a temperature of 0.3 K. Anton Heidemann tried to use it for an experiment involving CH4 on IN5 but encountered various problems and the experiment was a failure.

- In November 1982, independently of Caussignac/Benoît, Karl Neumaier developed the solution which is still in use at the ILL today.

Michel Caussignac and Alain Benoît

Jean-Louis Tholence (CNRS-CRTBT) tells the story of how this invention came about:

When I came back from the United Stated in 1979, I asked Alain Benoît if it would be possible to make a very small dilution unit (with a diameter of 29 mm) that could replace the adiabatic demagnetization cell I was using for magnetization measurements. It was then that he suggested a dilution insert without a 1 K chamber, which worked very well down to 50 mK and did not heat up when the whole unit was moved (the dilution unit was connected to the sample via a long copper braid). Other labs tried moving just the sample, which was thermally connected to the mixing chamber, but these attempts failed as the sample heated up.

Doing away with the 1 K chamber made it possible to remove one pump unit but needed a much more powerful helium compressor. The development of this innovative device is described in Michel Caussignac’s thesis [1]. Serge Pujol recalls that tests were carried out on the diffractometer D1B by the team Caussignac/Benoît/Flouquet.

The construction of this device under license was first offered to Oxford Instruments (who weren’t interested), and then to Air Liquide, who marketed the product Minidil 70 (which was too expensive). Then in 1992, the company Concept Soudure (Gilbert Ardin, a former employee of CNRS/CRTBT) built it at a price of 300 k€. Finally, Patrick Pari, a student of Alain Benoît, continued to pursue this work with the company Cryoconcept.

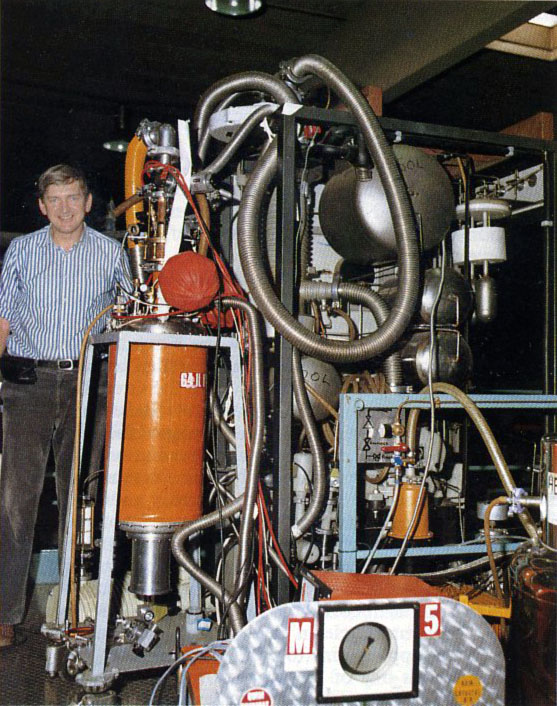

Karl (Charlie) Neumaier

In September 1981, Karl (Charlie) Neumaier - a cryogenics specialist who had come from the Meissner-Institut in Garching - was conducting an experiment on IN13 with Anton (Toni) Heidemann on LuH0.01. To get down to the temperature they wanted to work at, the Oxford Instruments dilution cryostat brought to the ILL by Paul Hilton needed a whole week. Toni and Charlie were exasperated, and quite rightly so!

Charlie asks:

Do you want me to build you a top-loading system that’s more practical and much faster?

Toni replies:

YES!

Independently of the Benoît/Caussignac team, Charlie then designed and built the first “3He/4He dilution refrigerator insert for standard ILL cryostats [2,3]. In his own words:

It was a completely unbureaucratic affair between Toni (Anton Heidemann) and myself, without any detailed study by a committee of important people. According to the theory of aerodynamics, bumblebees can’t fly, but as they don’t know this, they fly just the same. You can apply the same kind of reasoning to the insert. We attempted the impossible and were lucky enough to succeed.

This extremely compact device slid into the Orange cryostat in place of the normal sample holder. Nothing could be simpler! It was not only much simpler to use and to maintain, but was also cheaper than a dedicated dilution cryostat.

Dominique Brochier (Head of the Sample Environment Service), who was struggling with the dilution cryostats in use in those days, tells how he felt very relieved when the "Charlie" inserts came on the scene! Karl then trained Jean-Louis Ragazzoni to use this new technology.

During the long reactor shutdown (1982-1983), Jean-Louis Ragazzoni, Peter Suttling and Roger Chung built around twenty inserts, although, at the beginning at least, the mixing chamber heat exchanger and the continuous heat exchanger were still made in Garching by Karl Neumaier himself. Some of these inserts were then exported (1 to Rutherford Lab, 2 to NIST, 1 to LAP, 1 to Max Planck Munich) and the ILL kept 2. The remainder would be used for spare parts. The laboratories were charged 115 000 francs (or almost 35 000 € in 2014 value) for an insert and its Orange cryostat. According to Jean-Louis Tholence (CNRS), the dilution cryostats available on the market were around 5 times more expensive, although it is difficult to know whether or not this comparison is based on full systems.

Charlie’s logbook

29/07/82 | Leak, very large |

11/09/82 | T =0.5 K, leak, large |

10/11/82 | T = 0.09 K, no leak detectable |

14/11/82 | T = 0.06 K |

18/11/82 | CH4 at 40 mK |

1982 | The ILL was considering buying a second dilution cryostat from Oxford Instruments. Anton Heidemann went to see the Director (B. Fender) and convinced him to cancel the order and opt for dilution inserts. |

Jan. 83 | CH4 on IN5 at T = 100 mK. Jean-Louis Ragazzoni notes:

|

End Jan. 83 | NbOxHy on IN12 |

Sept. 83 | Mn acetate on IN13 |

Dec. 83 | NbOxHy on IN6 |

[…] | |

2002 | Workhorse for mK experiments |

2007 | A modified version of the 2nd insert built by Charlie and Jean-Louis was still working. |

Subsequent developments

After his success of 1982, Karl Neumaier continued his work and developed a very special heat exchanger in the form of conical windings stacked inside each other (like a pile of upside-down Chinese hats) which surprised the cryogenics specialists of SANE. This is what Karl Neumaier has to say about it:

In Garching, I replaced the 1 K stage of the dilution insert with an internal precooling heat exchanger type “chapeau chinois” (as named by Jean-Louis Ragazoni). The cool time was a bit longer, but it was possible to reach 50 mK in 5 hours after closing the vacuum jacket. Actually there are five units more or less permanently used.

It was J. Kraus from our institute who, in 1976, produced the first dilution unit without a 1 K pot, at the same time as De Whaele in Eindhoven. His dilution unit worked very well but was limited by its turbulent impedance, which made it impossible to vary the flow rate. It took me a long time to find an impedance that was both high (absolutely essential for small dilution units) and at the same time laminar, with which I could vary the flow rate between 10 and 50 µmoles/s.

In fact, this approach, just like the one developed by Causignac and Benoît, is justified in certain contexts, but to a much lesser extent in the case of the ILL. The current inserts perform well without the need for this type of assembly, which is difficult to produce. However, they require that the liquid helium cryostat has a 2 K stage, which has the disadvantage of making it difficult to work at temperatures above 1.8 K. To do so, you must pump the mixture and then add an exchange gas into the insert in order to switch from "dilution mode” to "cryostat mode”. This is a manual procedure that can only be carried out by those with “insider” knowledge.

In the framework of its upgrade programme Endurance, the ILL aims to automate this transition from T < 1.8 K to T > 1.8 K.

Extracts from ILL Annual Reports up to 1990

The ILL Annual Reports and Karl (Charlie) Neumaier’s log book show just how quickly the dilution inserts were developed [5] and how rapidly they became successful:

1981: the report mentions a "He-3 system which provides temperatures down to 70 mK" but does not give any more details.

1982: the report states that the "Pocket dilution refrigerator" developed by K. Neumaier has achieved a temperature of 40 mK. Nowadays, we tend to use the term “dilution insert”.

1983: the dilution inserts are extremely successful and allow a complete sample change in just 4 hours. The ILL has produced around twenty inserts for itself and external laboratories.

1984: The ILL’s two 25 mK inserts are in use and have completed a total operating period of 40 days. In less than 4 years, the inserts have overtaken dilution cryostats.

1987: D. Brochier writes: "The cryostats developed in previous years are now used for routine operation."

1990: The report mentions the validation of a new type of insert designed by the Institut LAPP (Annecy) and the Walther-Meissner Institut (Garching). This is still very much a "Charlie" insert.

In the same way that the Orange cryostats made it "easy" to achieve low temperatures down to 1.5 K, the dilution inserts helped to popularise the routine use of very low temperatures down to 50 mK under the conditions required for neutron experiments. Currently, 80% of very low temperature experiments carried out at the ILL use dilution inserts, 15% use 3He inserts and the rest use dilution cryostats.

References

- M. Caussignac, PhD thesis, University of Montpellier, 5 June 1980.

- Neumaier K., Heidemann A., Magerl A. "A dilution refrigerator insert for standard ILL cryostats", Rev. Phys. Appl. 19, 773-774 (1984).

- K. Neumaier, A. Heidemann, A. Magerl, Rev. Phys. Appl. 19, 773 (1984)

- Presentation by K. Neumaier in honour of Anton Heidemann, ILL 29/11/2002.

- In Charlie’s own words:

Anne Marie De Goer, my tutor at the CENG asked me:

[A-M] How was it possible to produce the insert in such record time?

[Karl] I designed and assembled the insert myself.

[A-M] You assembled it yourself?

[Karl] Yes!

[A-M] Ah, now I understand! At the CENG no senior staff member would ever pick up a soldering iron."