LHe Level Monitors

ILL Liquid Helium Level Monitors

The liquid helium levels of our cryostats are monitored with electronics designed from industrial components. The levels are measured with superconducting sensors built internally. The calibrations, measurements, alarms and automated refills are easily managed with a process controller (Eurotherm model 3504).

Intuitive interface

The unit displays permanently the liquid helium level with a bar graph and a number that are visible quite far away from the cabinet. The interval of time between readings is chosen by the user with the aim to reduce the boil-off. Only one button is required to start / stop manually a refill. The message "Refilling..." is displayed when filling.

When the low level is reached, an alarm is displayed in red and a fill is automatically launched. If the fill fails after a certain amount of time, it is automatically stopped. The alarm is maintained and the level continues to be measured and displayed until the user acknowledges the alarm.

Easy settings

The level monitor is calibrated in a very few steps:

- fill the cryostat in liquid helium

- enter the Settings mode

- raise the superconducting sensor and confirm the low level value

- lower the superconducting sensor and confirm the high level value

- quit the Settings mode

The low and high levels, the alarm level and the fill timeout can easily be modified from the Settings menus according to the user wishes.

Full remote control

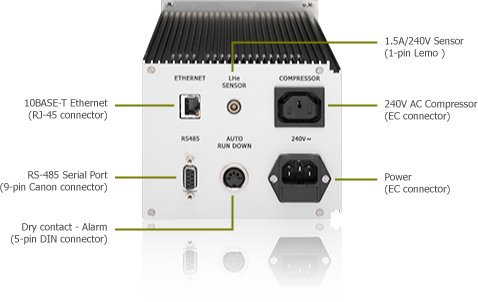

Computer control via RS-485 and Ethernet is available. All parameters can be read and set, even the configuration of the sensor. The communications are based on the Modbus communications protocol which has become a de facto standard in industry. We provide a Modbus XOP and a Procedure for controlling the level monitor with Igor Pro.

Instruction Manual

The ILL liquid helium level monitor has been carefully designed and manufactured to provide hours of trouble free service. Its user interface has also been designed so as to simplify as much as possible its operation. The monitor also has several features that are not available on other commercial systems: a large display for easy reading on large instruments and a full remote access allowing users to monitor different cryostats without the need for recalibrating.

The level monitor uses a superconducting sensor and provides a 240V AC signal to control the compressor used to fill a cryostat from a dewar. It is delivered fully tested and ready to be calibrated. We describe below how to install, operate and remotely control the level monitor.

Operation

The monitor manages the readings and the fills. The user can easily set the low and high levels, the alarm level and the fill timeout. The refills are started when the low level is reached or when the user presses the command "REFILL". The fill cycle will end when the level reaches the high limit, when the fill timeout expires, or when the user presses the "STOP" command. When the fill timeout expires, the refill is aborted and the alarm remains active until the user acknowledges it.

Interfacing

The monitor can be remotely controlled through a RS485 or Ethernet link using the Modbus communication protocol (public function code 3).

Technical Specifications

The ILL liquid helium level monitor is presently delivered with the version 1.07 of the soft-wired program installed and preset with Orange cryostats parameters. The default interval of time between readings is 30 min. The minimum and maximum values of the sensor resistance that can be managed by the unit are respectively 3 and 270 Ω. Remote control is performed using the registers listed below.

Firmware Update

The latest release 1.07 adds the ability to detect a sensor break, fixes a bug allowing the modification of the release number, and another bug allowing the display of negative values.

Size and Weight

The monitor fits within a 19"/3U chassis.

- Height: 129 mm (5.1 inches)

- Width: 143 mm (5.6 inches)

- Depth: 355 mm (14 inches)

- Weight: 2.70 kg (5.95 pounds)

Modbus registers

| Description | Min | Max | Address |

|---|---|---|---|

| LHe level value | -2 | 120 | 4965 |

| Interval of time between readings in min | 0 | 100 | 4997 |

| Alarm set point in % | 0 | 100 | 4969 |

| Low level set point in % | 0 | 100 | 4970 |

| High level set point in % | 0 | 100 | 4963 |

| Fill command | 0 | 1 | 4976 |

| Fill timeout value in min (default: 30min) | 0 | 100 | 11272 |

| Fill timeout error status | 0 | 1 | 11273 |

| Auto-run-down status | 0 | 1 | 10265 |

| Firmware version | 1 | 10 | 4977 |

Electrical and operating requirements

Contact us if you need a 100V AC / 60 Hz unit.

- Line voltage: 240V AC

- Frequency: 50Hz

- Operating temperature: 10 to 35°C (50 to 95 °F)

- Storage temperature: -24 to 45°C (-13 to 113 °F)

- Relative humidity: 5 to 85% noncondensing

Firmware Updates

Please find below the release history and some instructions for updating the firmware. To get the most recent release of the firmware, please contact us.

Release History

- 1.00 - Initial release

- 1.01 - Modified the pages for simplifying the use of the controller.

- 1.02 - Fixed an issue encountered when reading long sensors.

- 1.03 - Changed reading method so that the level is updated during fills.

- 1.04 - Fixed a bug in the routine managing the timeout.

- 1.05 - Added a page for displaying the firmware release number.

- 1.06 - Added a variable for remotely requesting the fill of the helium bath.

- 1.07 - Fixed a bug allowing the modification of the release number, fixed a bug displaying negative values, added the ability to detect a sensor break.

Instructions for updating the controller

- Install iTools (available here),

- Connect the controller to the computer with an Ethernet cable,

- Configure the TCP/IP parameters of the computer:

- Select the Connection panel and click on TCP/IP Properties,

- Enter the fixed IP address 192.168.248.1 (192.168.248.253 for NOMAD),

- Enter the subnet mask 255.255.255.0,

- Enter the gateway address 192.168.248.0,

- Launch iTools and open the OPC Server window,

- Open the "Scan for TCP hosts..." panel from the Add/New TCP Network Port menu command,

- Enter the TCP/IP address 192.168.248.202 (standard address of the LHe level monitor),

- Launch the scan and stop it once the controller detected,

- Reduce the OPC Server window (do not close it!),

- Click on the Scan icon of the main iTools toolbar and launch a search for connected instruments,

- After the scan, click on the Load icon of the main toolbar, select the new firmware and launch the update.